Plastics are inexpensive and durable as a result levels of plastic production by humans are high. However the chemical structure of most plastics renders them too resistant to many natural processes of degradation and as a result, they are slow to degrade together these two factors have led to a high prominence of plastic pollution in the environment millions of animals are killed by plastic every year. But there are many ways we can reduce plastic pollution by converting waste plastic into a helpful resource.

Chemical Conversion of Plastic Waste into Fuel

We are going to see how plastic is turned into fuel. Imagine a world where a Gigantic of plastic waste can be converted into useful resources again and used for other purposes. Chemical recycling is an attractive way to reduce the explosive growth of plastic waste and disposal problems. We know plastic is just crude oil that has been proposed in different ways and with pyrolysis we can reverse this process.

What is Plastic Pyrolysis?

Plastic pyrolysis is a very effective process where plastic is exposed to high temperatures in an oxygen-free environment. Pyro means heat and lysis means breakdown at any given temperature the molecule is in the vibrating stage this is called molecular vibration.

The frequency at which molecules vibrates is directly proportional to the temperature of molecules during pyrolysis the molecules are subjected to very high temperatures leading to very high molecular vibrations at this high molecular vibration every molecule in the object is stretched and shaken to such an extent that molecules start breaking down into smaller molecules this is Pyrolysis.

Plastic is hard to break down, and we must add a catalyst to help break the chemical bonds. A Catalyst is a substance that speeds up a chemical reaction but is not consumed by the reaction and mostly Fly ashes obtained from coal combustion or zeolite etc is used as the catalyst.

Finally, waste plastic is converted into approximately 80% oil 15% gas, and 5% carbon black or Ash. Let's have a look into how plastic is actually converted into a useful resource there are many steps involved in the plastic pyrolysis process but we are simply going to see 5 simple steps.

Process of Plastic Pyrolysis

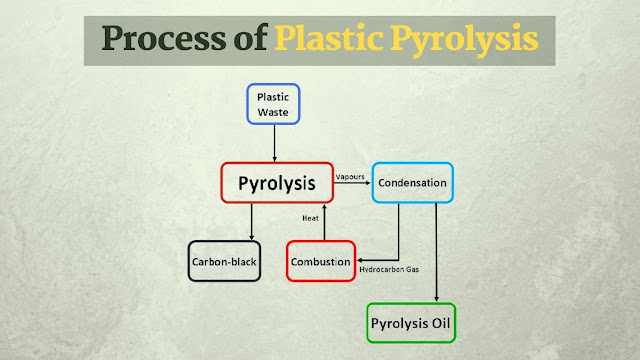

Waste plastic to pretreatment process, spreader, pyrolysis, condensation, and refining. Waste plastic is first sent into a pretreatment process that removes any foreign matter and then sent into a plastic shredder is a machine used to cut the plastic into smaller pieces the smaller pieces of plastic are then sent into a densifier that comprises the smaller plastic pieces into a dense material to facilitate easy and storage or handling then they are sent into what chamber where the pyrolysis of plastic takes place.

The plastic is heated approve 450-degree centigrade in the presence of the catalyst and in the absence of oxygen. The plastic is slowly melted and converted into a gas-gaseous state then the gas is sent into a condenser then the condensation takes place.

Condensation means the conversion of a vapor or gas to a liquid then it is sent into an oil refinery chamber. Finally, plastic waste is refined into approximately 80% oil 15% cash 5% carbon black, or Ash. This oil is used as heating material and sold to cement glass-ceramic electric power factories, etc.

And also used in heavy oil generators for electricity generation and it is a deep process into diesel oil with a distillation plant the final oil can be used in truck tractors and many more. 15% gas is recycled into the furnace to heat the reactor instead of using coal, wood, oil, etc and the remaining carbon black is used as slag for construction and also used as a replacement for coal.

Some drawbacks and advantages of plastic pyrolysis

Drawbacks

Pyrolysis is an energy-consuming process more energy has to be put in to treat the waste that can actually be recovered pyrolysis of plastic can never be sustainable etc.

Advantages of plastic pyrolysis

It reduces the waste going into landfills and greenhouse gases and reduces the risk of water pollution it creates new jobs for lower-income people based on the quantity of waste generated in the region and extra which in town provides public health benefits through waste cleanup and extra and this is how waste plastic is turned into a usable resource by using waste pyrolysis.

0 comments

comment down what do you think?